Showing all 2 results

-

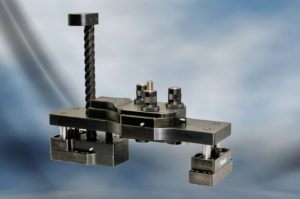

Model 3100 Follow Along In-Die Tapping Units

Single and Multi-Spindle Units (For strip lift over 1/8″” (3 mm)

Tapping Capacity (#2-56 to 1/4-20 or M2 to M6)

Conserve die space with multi-spindle units

Multi-spindle units made to customer centerline specifications

Send part prints/strip layouts to have multi-spindle applications quoted.

Self-contained follow along unit reduces stripper travel v. standard tapping units

Increase production speeds 30-60% versus standard unitsDesign and Product Specifications

Tapping capacity(#2-56 to 1/4-20 or M2 to M6)

Press strokes up to 10″”

Press speeds up to 150 SPM

2D & 3D design files

Complete design support

Die review of tapping stations

Complete bill of material for standard and multi-spindle units

Tap sensors available to detect broken taps

One Year/ One Million stores limited warrantyEconomical

Tapping heads can be moved to multiple dies

Use standard roll form taps for the manufacturer of your choice

Low maintenance driver only requires a few minutes of basic maintenanceConvenient

Simple design & installation saves tooling costs

Coolant ring allows for through the tapping head coolant

Multiple mounting options allows tapping head to be removed from die while in the press

Change taps in press in under a minute -

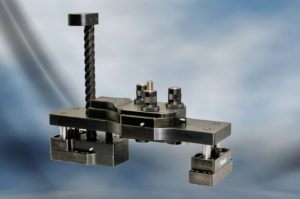

Model 6100 Follow Along In-Die Tapping Units

Single and Multi-Spindle Units (For strip lift over 1/8″” (3 mm)

Tapping Capacity (#6-32 to 1/2-20 or M3.5 to M12)

Conserve die space with multi-spindle units

Multi-spindle units made to customer centerline specifications

Send part prints/strip layouts to have multi-spindle applications quoted.

Self-contained follow along unit reduces stripper travel v. standard tapping units

Increase production speeds 30-60% versus standard unitsDesign and Product Specifications

Tapping capacity (#6-32 to 1/2-20 or M3.5 to M12 )

Press strokes up to 18″”

Press speeds up to 100 SPM

2D & 3D design files

Complete design support

Die review of tapping stations

Complete bill of material for standard and multi-spindle units

Tap sensors available to detect broken taps

One Year/ One Million stores limited warrantyEconomical

Tapping heads can be moved to multiple dies

Use standard rollform taps for the manufacturer of your choice

Low maintenance driver only requires a few minutes of basic maintenanceConvenient

Simple design & installation saves tooling costs

Coolant ring allows for through the tapping head coolant

Multiple mounting options allows tapping head to be removed from die while in the press

Change taps in press in under a minute